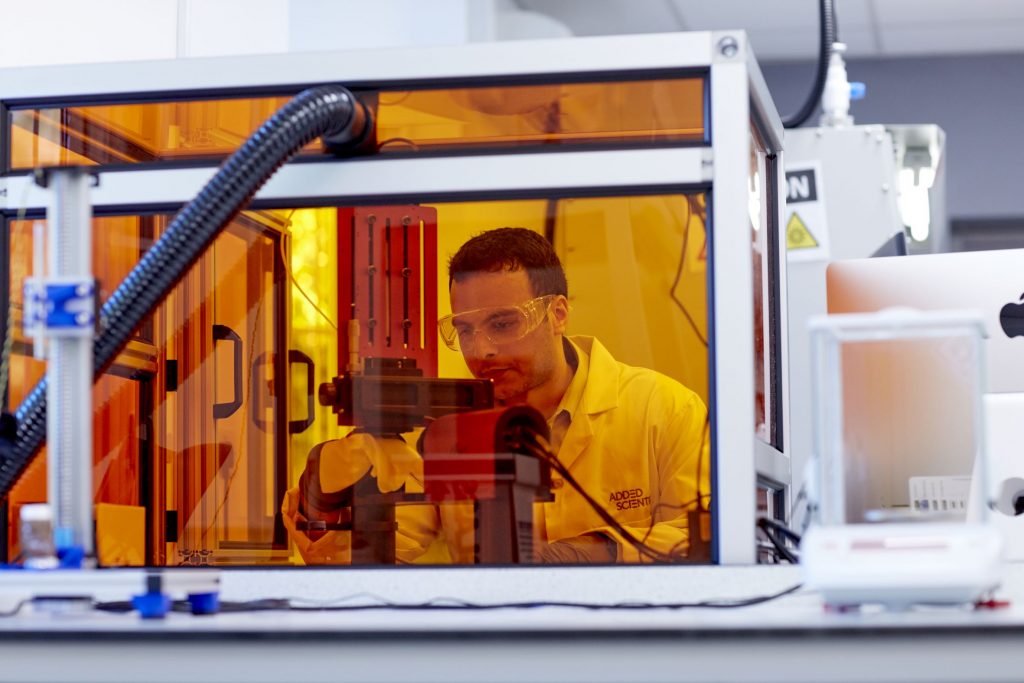

The Xaar 1201 printhead is proving instrumental in helping Nottingham-based research organisation, Added Scientific, establish the suitability of inkjet printing in the manufacture of personalised pharmaceutical pills, where dosages could be tailored to individuals on an industrial scale.

Building on research conducted by the University of Nottingham, where excipients (everything but the active pharmaceutical ingredient [API]) have been developed, Added Scientific initiated a project with its collaborators Xaar and AstraZeneca to look at the long-term scalability and suitability of inkjet printing in dispensing APIs. The project was funded under the Industrial Strategy Challenge Fund’s Medicines Manufacturing Challenge, with support from Innovate UK.

“Inkjet printing offers the ability to digitally control the printing with its precision placement of tiny droplets a few picolitres in size and the capability to place multiple materials to create complex multi-functional objects in 2D & 3D,” comments Craig Sturgess, Research Manager for Added Scientific.

“Trial research carried out previously has shown that inkjet offers a real potential for printed medicines. This project was designed to answer questions pharmaceutical companies have around the suitability of inkjet printing in dispensing APIs at a scale that made both manufacturing and economic sense.”

Utilising the Xaar 1201 printhead with one of the formulations developed at the University of Nottingham, the project evaluated the impact on the API as well as the printhead’s ability to operate in Good Manufacturing Practice (GMP) conditions whilst also determining if the formulation had an effect on the printhead life. Alongside these experimental trials, data from conventional tablet manufacturing from AstraZeneca was evaluated against inkjet printing process times.

Results from this pilot project found that, in production trials of 1000 dosage forms manufactured in batches of 100, there were significant time-savings in unit process times from inkjet printing when compared to traditional manufacturing methods with no issues or interaction with the API in the Xaar 1201 printhead or impact on the printhead’s life.

“The Xaar 1201 is ideal for a wide range of industrial applications including Advanced Manufacturing due to its ability to print fluids with a range of viscosities, reactivity and conductivity,” says Mike Seal, Business Development Manager, Advanced Manufacturing, at Xaar. “This pilot project has demonstrated the Xaar 1201’s versatility for pharmaceuticals and how inkjet printing is proving itself to have the potential to drive innovation as well as efficiencies in many areas of 21st century life.”

“These are exciting times,” concludes Craig. “Our project has clearly shown that printing personalised medicines – with all their advantages of dose and design freedom – is no longer just a theory, but a scalable and economic reality for pharmaceutical companies and we look forward to extended trials to confirm these findings.”