The Internet serves as a gateway to a world of data, communication, and automation, revolutionizing how factories and manufacturing plants operate. The possibilities are endless, from streamlining supply chains to providing live chat support. By implementing some strategies, businesses can not only keep up with the demands of modern manufacturing but also lead the way toward a more connected and efficient future. By leveraging the power of connectivity, industries can unlock many opportunities to enhance productivity, efficiency, and overall performance. In this article, we’ll explore five key strategies companies can employ to maximize their industrial production through Internet integration.

Business automation with IoT

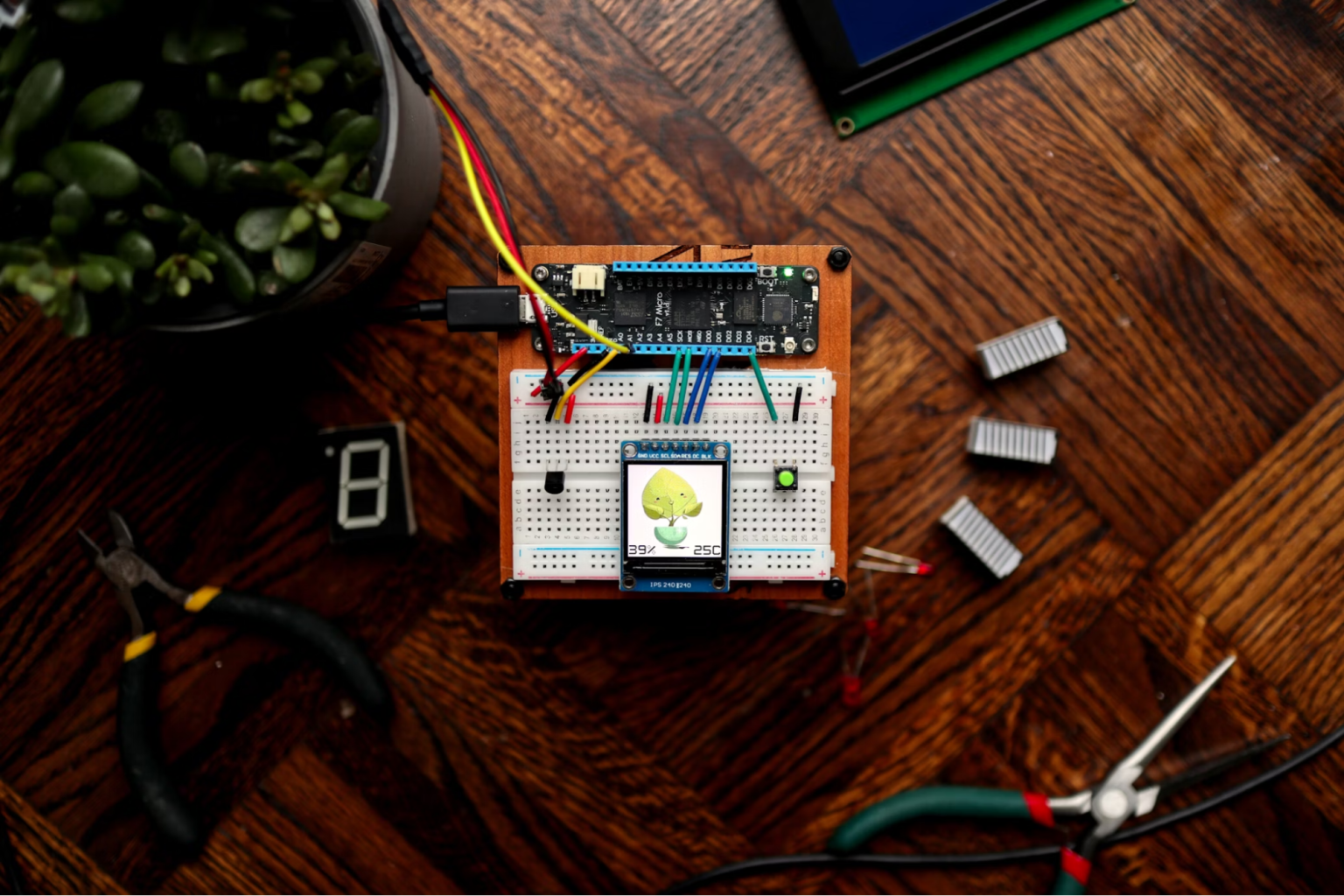

With the advent of the IoT gateway, businesses now have a powerful tool to streamline operations like never before. By integrating IoT devices into their processes, companies can automate various tasks, provide live chat support, gather valuable data, and make informed real-time decisions.

Business Automation Strategies with the IoT:

- Asset Tracking and Management: IoT sensors can be deployed to track the location and status of assets in real time, enabling better utilization and maintenance schedules.

- Predictive Maintenance: By collecting data from IoT-enabled machinery, businesses can predict when equipment is likely to fail, allowing for proactive maintenance and minimizing downtime.

- Supply Chain Optimization: IoT devices can monitor inventory levels, track shipments, and optimize routes, leading to more efficient supply chain management.

- Smart Energy Management: IoT sensors can monitor energy usage across facilities, allowing businesses to identify areas for improvement and reduce costs.

- Enhanced Customer Experience: By leveraging IoT data, businesses can personalize products and services, anticipate customer needs, and provide a seamless experience.

Business automation with the IoT offers immense potential for companies to streamline operations, increase productivity, and deliver exceptional value to customers.

Data Analytics

In the field of industrial production, leveraging the power of data analytics through Internet integration has enormous potential to optimize processes, increase efficiency, and drive innovation. By leveraging the Internet of Things and advanced analytics, industries can derive valuable insights from their operational data to improve decision-making and productivity.

Ways Data Analytics Enhance Industrial Production Through Internet Integration:

- Predictive Maintenance: Utilizing IoT sensors to monitor equipment health in real-time enables predictive maintenance, minimizing downtime and optimizing production schedules.

- Quality Control: Analyzing data from sensors and production lines allows for early detection of defects, ensuring product quality, and reducing waste.

- Supply Chain Optimization: Integrating data analytics across the supply chain facilitates better demand forecasting, inventory management, and logistics planning.

- Energy Efficiency: Monitoring energy consumption through IoT devices enables the identification of areas for optimization and cost savings.

- Process Optimization: Analyzing production data helps identify bottlenecks, optimize workflows, and improve overall efficiency.

By integrating data analytics with Internet-connected devices and processes, industrial production can be transformed to become more flexible, efficient, and responsive to market demands.

Predictive Maintenance

Predictive maintenance represents a significant advancement in industrial maintenance strategies. This allows businesses to transition from reactive to proactive approaches. By integrating IoT data with predictive analytics, industrial facilities can anticipate equipment failures before they happen. This enables timely interventions to prevent costly downtime and optimize maintenance schedules.

Key Aspects of Predictive Maintenance Using IoT and Predictive Analytics:

- Data Collection: IoT sensors continuously collect data on equipment performance, including temperature, vibration, and other relevant metrics.

- Data Analysis: Predictive analytics algorithms analyze the collected data to identify patterns, anomalies, and early indicators of potential equipment failures.

- Predictive Models: By leveraging machine learning and statistical techniques, predictive maintenance models are developed to forecast equipment failures accurately.

- Timely Interventions: Based on predictive insights, maintenance teams can schedule interventions such as repairs or component replacements before a failure occurs, minimizing downtime and production losses.

- Optimization of Maintenance Schedules: Predictive maintenance enables businesses to optimize maintenance schedules by performing interventions only when necessary, reducing costs associated with unnecessary maintenance tasks.

Predictive maintenance, powered by IoT data and predictive analytics, offers industrial facilities a proactive approach to equipment maintenance. By predicting failures before they happen, businesses can avoid costly downtime, optimize maintenance resources, and improve overall operational efficiency.

Supply Chain Optimization through Internet Integration:

In supply chain management, Internet integration has revolutionized operations by providing real-time visibility and transparency across the entire supply chain ecosystem. Businesses can use IoT sensors and data analytics to enhance efficiency, reduce costs, and improve resilience throughout the supply chain lifecycle.

Key Aspects of Supply Chain Optimization Using Internet Integration:

- Real-time Visibility: IoT sensors track inventory movement and monitor conditions in real time, providing stakeholders with accurate and up-to-date information on inventory levels, location, and status.

- Demand Forecasting: Data analytics algorithms analyze historical data and market trends to forecast demand more accurately, enabling businesses to optimize inventory levels and minimize stockouts or overstock situations.

- Efficient Inventory Management: With real-time data insights, businesses can optimize inventory levels, reduce carrying costs, and improve inventory turnover rates.

- Logistics Optimization: Internet integration facilitates dynamic route planning, load optimization, and shipment tracking, leading to more efficient transportation operations and reduced lead times.

- Supply Chain Resilience: By leveraging real-time data and predictive analytics, businesses can identify potential disruptions and implement proactive measures to mitigate risks, ensuring continuity of operations.

By leveraging IoT sensors and data analytics, businesses can streamline processes, reduce costs, and improve overall supply chain resilience, ultimately driving greater efficiency and competitiveness in the market.

Smart Factory Implementation

Enabled by Internet integration, smart factories leverage IoT devices, data analytics, and machine learning algorithms to revolutionize traditional manufacturing processes.

Key Aspects of Smart Factory Implementation:

- IoT Integration: IoT devices collect real-time data from machinery, sensors, and production lines, providing insights into equipment performance, energy consumption, and product quality.

- Data Analytics: Advanced analytics tools analyze vast amounts of data generated by IoT devices, uncovering patterns, anomalies, and opportunities for optimization.

- Machine Learning: Machine learning algorithms learn from historical data to predict equipment failures, optimize production schedules, and improve overall efficiency.

- Real-time Optimization: Smart factories dynamically adjust production processes in response to changing demand, market conditions, and resource availability.

- Demand-driven Production: By integrating customer demand data with production systems, smart factories produce goods on demand, minimizing inventory costs and reducing waste.

In conclusion, integrating the Internet into industrial production processes offers unparalleled opportunities for enhancing efficiency, productivity, and competitiveness. By embracing these five strategies industries can pave the way for a more connected, agile, and optimized future.